Introduction to Cell Therapy

Cell therapy represents a promising new frontier in medicine, especially in treating diseases such as cancers, inflammatory diseases, and chronic degenerative disorders by manipulating or replacing cells to restore function or fight disease. However, a major challenge in cell therapy product (CTP) manufacturing is quickly and effectively ensuring that cells are free from contamination before being administered to patients.

The Challenge of Sterility Testing

Existing sterility testing methods, based on microbiological methods, are labor-intensive and require up to 14 days to detect contamination, which could adversely affect critically ill patients who need immediate treatment. While advanced techniques such as rapid microbiological methods (RMMs) can reduce the testing period to seven days, they still require complex processes such as cell extraction and growth enrichment mediums, and they are highly dependent on skilled workers for procedures such as sample extraction, measurement, and analysis.

A Novel Method for Detecting Microbial Contamination

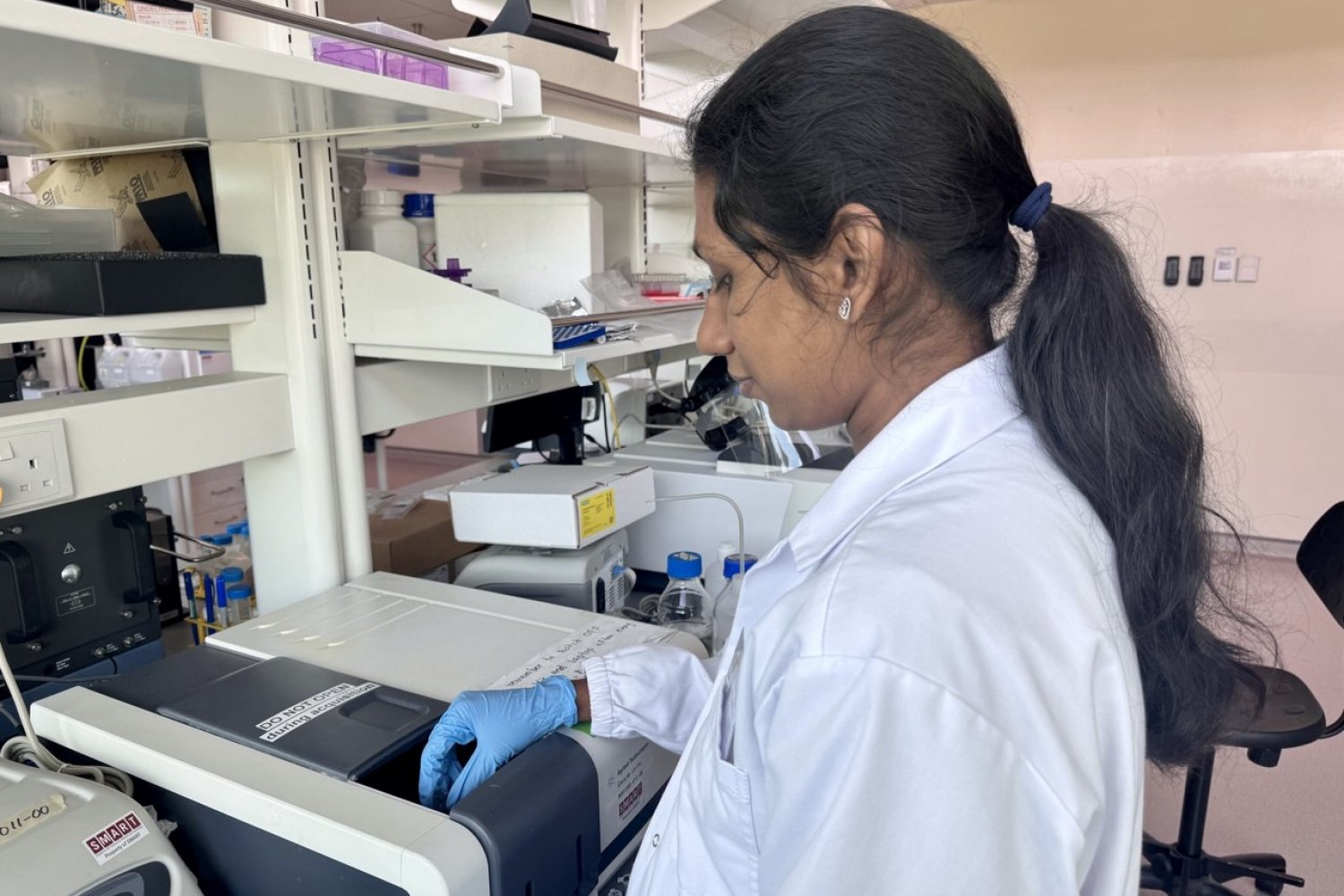

Researchers from the Critical Analytics for Manufacturing Personalized-Medicine (CAMP) interdisciplinary research group of the Singapore-MIT Alliance for Research and Technology (SMART), MIT’s research enterprise in Singapore, in collaboration with MIT, A*STAR Skin Research Labs, and the National University of Singapore, have developed a novel method that can quickly and automatically detect and monitor microbial contamination in cell therapy products early on during the manufacturing process. By measuring ultraviolet light absorbance of cell culture fluids and using machine learning to recognize light absorption patterns associated with microbial contamination, this preliminary testing method aims to reduce the overall time taken for sterility testing and, subsequently, the time patients need to wait for CTP doses.

Advantages of the New Method

This method offers significant advantages over both traditional sterility tests and RMMs, as it eliminates the need for staining of cells to identify labelled organisms, avoids the invasive process of cell extraction, and delivers results in under half-an-hour. It provides an intuitive, rapid “yes/no” contamination assessment, facilitating automation of cell culture sampling with a simple workflow. Furthermore, the developed method does not require specialized equipment, resulting in lower costs.

Future Applications and Research

Moving forward, future research will focus on broadening the application of the method to encompass a wider range of microbial contaminants, specifically those representative of current good manufacturing practices environments and previously identified CTP contaminants. Additionally, the model’s robustness can be tested across more cell types apart from MSCs. Beyond cell therapy manufacturing, this method can also be applied to the food and beverage industry as part of microbial quality control testing to ensure food products meet safety standards.

Conclusion

The novel method developed by researchers at SMART CAMP has the potential to revolutionize the cell therapy industry by providing a rapid and automatic way to detect microbial contamination in cell therapy products. This method can help reduce the time patients need to wait for CTP doses, which is especially crucial for critically ill patients who need immediate treatment.

FAQs

- Q: What is cell therapy?

A: Cell therapy is a medical treatment that involves manipulating or replacing cells to restore function or fight disease. - Q: Why is sterility testing important in cell therapy product manufacturing?

A: Sterility testing is important to ensure that cells are free from contamination before being administered to patients. - Q: What are the limitations of traditional sterility testing methods?

A: Traditional sterility testing methods are labor-intensive and require up to 14 days to detect contamination, which can delay treatment for critically ill patients. - Q: How does the novel method developed by researchers at SMART CAMP work?

A: The novel method measures ultraviolet light absorbance of cell culture fluids and uses machine learning to recognize light absorption patterns associated with microbial contamination. - Q: What are the advantages of the novel method?

A: The novel method is rapid, automatic, and does not require specialized equipment, resulting in lower costs and a simpler workflow.