Introduction to AI in Mining

Mining conglomerate BHP describes AI as the way it’s turning operational data into better day-to-day decisions. A blog post from the company highlights the analysis of data from sensors and monitoring systems to spot patterns and flag issues for plant machinery, giving choices to decision-makers that can improve efficiency and safety – plus reduce environmental impact.

How BHP Uses AI

For business leaders at BHP, the useful question was not “Where can we use AI?” but “Which decisions do we make repeatedly, and what information would improve them?” BHP describes the end-to-end effects of AI on operations, or as it puts it, “from mineral extraction to customer delivery.” Leaders had decided to move beyond pilot rollouts, treating AI as an operational capability. It started with a small set of problems that affected the company’s performance; places where change could be measured in results.

Portfolio Not Showcase

The company found it could avoid unplanned downtime of machinery, plus it tightened its energy and water use. Each use case addressing a small but impactful problem was given an owner and an accompanying KPI. Results were reviewed with the same regularity used for other operational performance monitoring elsewhere in the company.

Where BHP Uses AI Daily

In addition to BHP focusing specifically on areas such as predictive maintenance and energy optimisation, it gave consideration to using AI in more adventurous yet important operations such as autonomous vehicles and real-time staff health monitoring. Such categories can translate well to other asset-heavy environments, across logistics, manufacturing, and heavy industry.

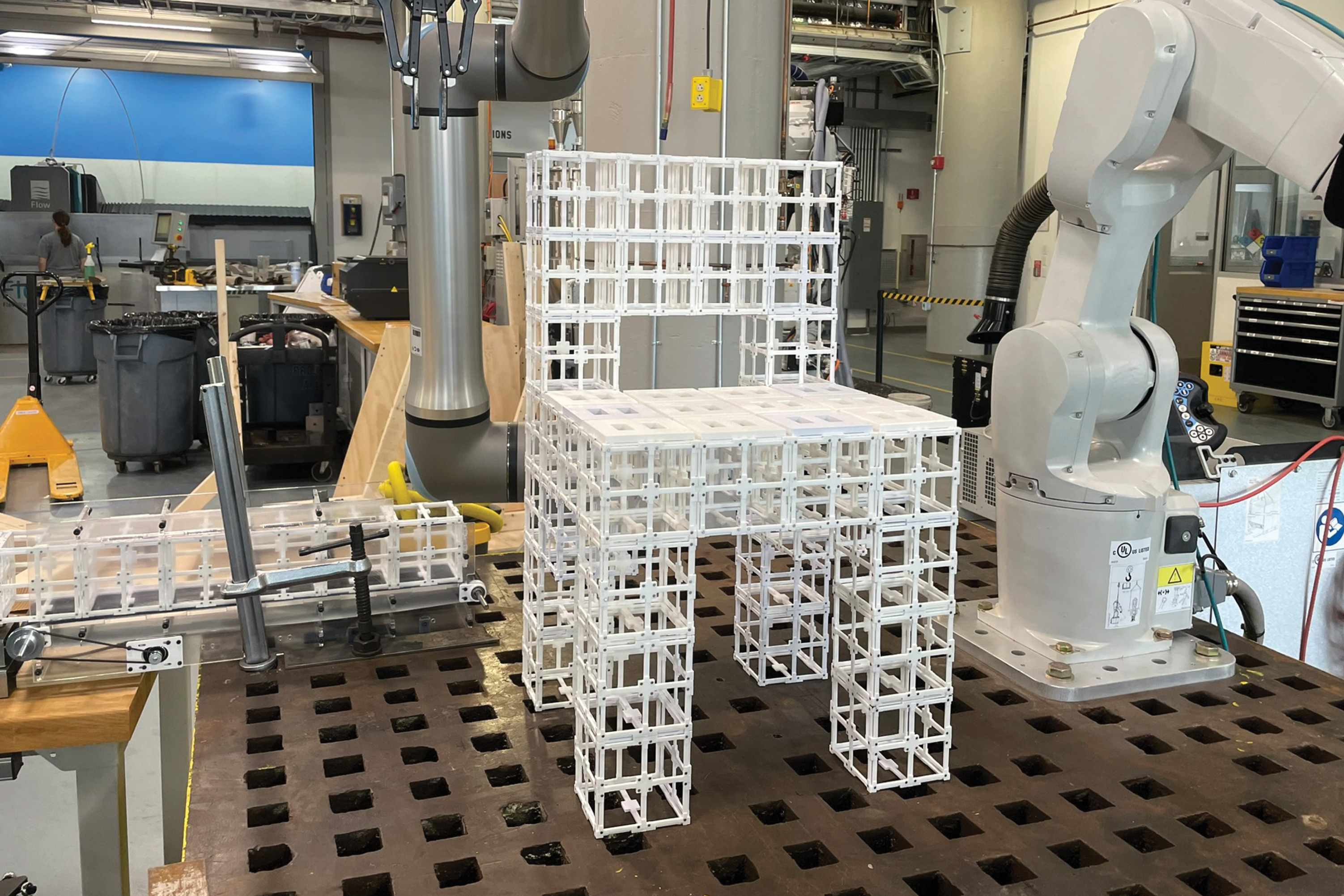

Predictive Maintenance

Predictive maintenance is the process of planning repairs in scheduled downtime to reduce unexpected failures and costly, unplanned stoppages. Here, AI models analyse equipment data from on-board sensors and can anticipate maintenance needs. This cuts breakdown numbers and reduces equipment-related safety incidents. BHP runs predictive analytics across most of its load-and-haul fleets and its materials handling systems. A central maintenance centre provides real-time and longer-range indications of machine health and potential failure or degradation.

Energy and Water Optimisation

Deploying predictive maintenance in this manner at its facilities in Escondida in Chile, the company reports savings of more than three giga-litres of water and 118 gigawatt hours of energy in two years, attributing the gains directly to AI. The technology gives operators real-time options and analytics that identify anomalies and automate corrective actions at multiple facilities, including concentrators and desalination plants.

Autonomy and Remote Operations

BHP is also using more advanced technologies like AI-supported autonomous vehicles and machinery. These are higher-risk areas, and the tech has been found to reduce worker exposure to risk, and cut the human error factor in incidents. At the company, complex operational data flows through regional centres from remote facilities. So, without the use of AI and analytics, staff would not be able to optimise every decision in the way that software achieves.

A Plan Leaders Can Run

Regardless of industry, decision-makers can draw learnings from BHP’s experiences in deploying AI at the (literal) coal-face. The following plan could help leaders in their own strategies to leverage AI in operational problem-areas:

- Choose one reliability problem and one resource-efficiency problem that operations teams already track, then attach a KPI.

- Map the workflow: who will see the output and what action they can take?

- Put basic governance in place for data quality and model monitoring, then review performance alongside operational KPIs.

- Start with decision support in higher-risk processes, and automate only after teams validate controls.

Conclusion

BHP’s use of AI is a great example of how the technology can be used to improve efficiency, safety, and reduce environmental impact in the mining industry. By focusing on specific areas such as predictive maintenance and energy optimisation, and using AI to support decision-making, BHP has been able to achieve significant gains. The company’s approach can be applied to other industries and can serve as a model for leaders looking to leverage AI in their own operations.

FAQs

Q: What is predictive maintenance?

A: Predictive maintenance is the process of planning repairs in scheduled downtime to reduce unexpected failures and costly, unplanned stoppages.

Q: How does BHP use AI in its operations?

A: BHP uses AI to analyse data from sensors and monitoring systems to spot patterns and flag issues for plant machinery, giving choices to decision-makers that can improve efficiency and safety – plus reduce environmental impact.

Q: What are the benefits of using AI in mining operations?

A: The benefits of using AI in mining operations include improved efficiency, safety, and reduced environmental impact.

Q: Can BHP’s approach to AI be applied to other industries?

A: Yes, BHP’s approach to AI can be applied to other industries, including logistics, manufacturing, and heavy industry.