Introduction to Sustainable Concrete

For weeks, the whiteboard in the lab was crowded with scribbles, diagrams, and chemical formulas. A research team across the Olivetti Group and the MIT Concrete Sustainability Hub (CSHub) was working intensely on a key problem: How can we reduce the amount of cement in concrete to save on costs and emissions?

The Challenge of Reducing Cement in Concrete

The question was certainly not new; materials like fly ash, a byproduct of coal production, and slag, a byproduct of steelmaking, have long been used to replace some of the cement in concrete mixes. However, the demand for these products is outpacing supply as industry looks to reduce its climate impacts by expanding their use, making the search for alternatives urgent. The challenge that the team discovered wasn’t a lack of candidates; the problem was that there were too many to sort through.

The Role of AI in Finding Alternatives

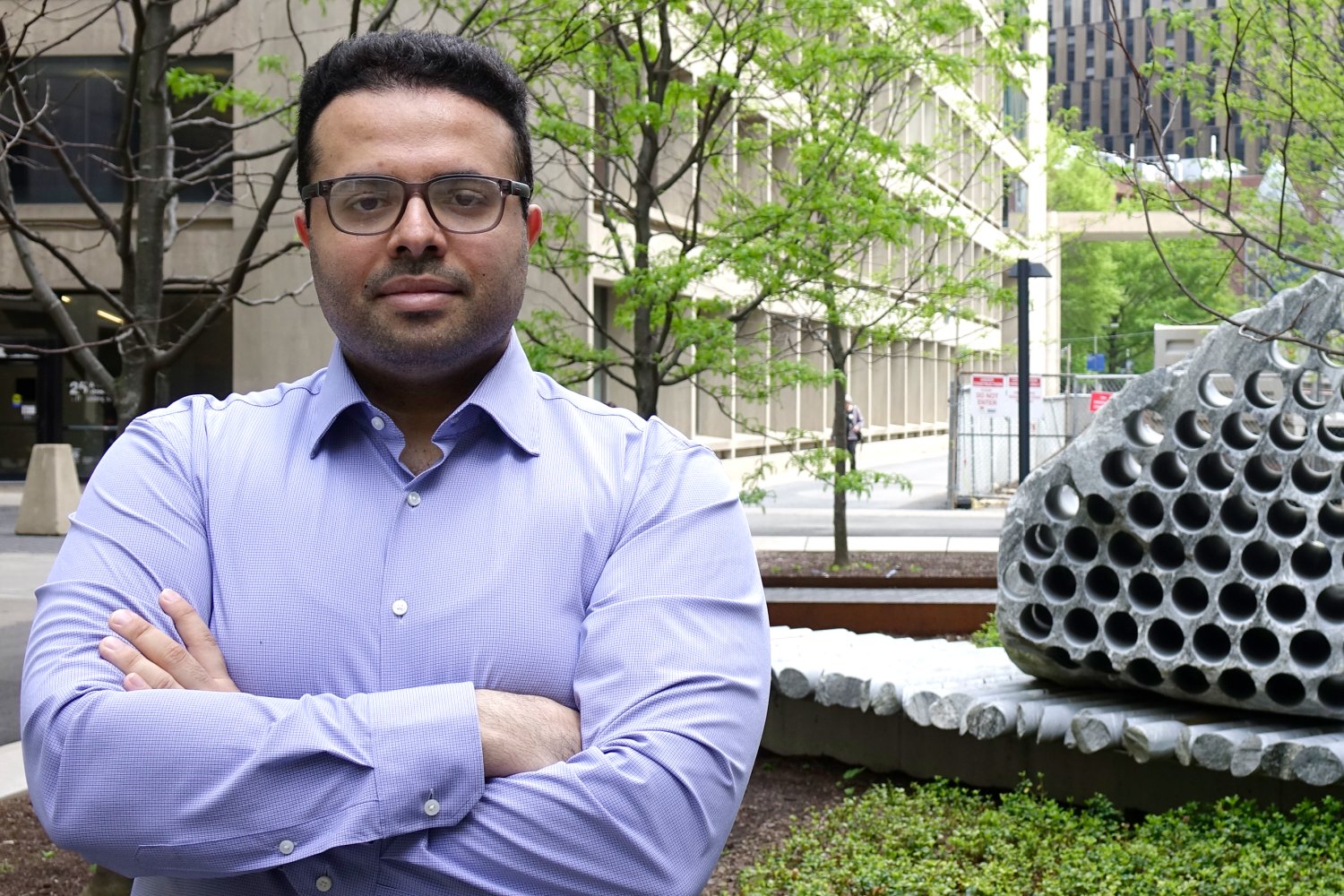

On May 17, the team, led by postdoc Soroush Mahjoubi, published an open-access paper in Nature’s Communications Materials outlining their solution. “We realized that AI was the key to moving forward,” notes Mahjoubi. “There is so much data out there on potential materials — hundreds of thousands of pages of scientific literature. Sorting through them would have taken many lifetimes of work, by which time more materials would have been discovered!” With large language models, like the chatbots many of us use daily, the team built a machine-learning framework that evaluates and sorts candidate materials based on their physical and chemical properties.

Key Properties of Alternative Materials

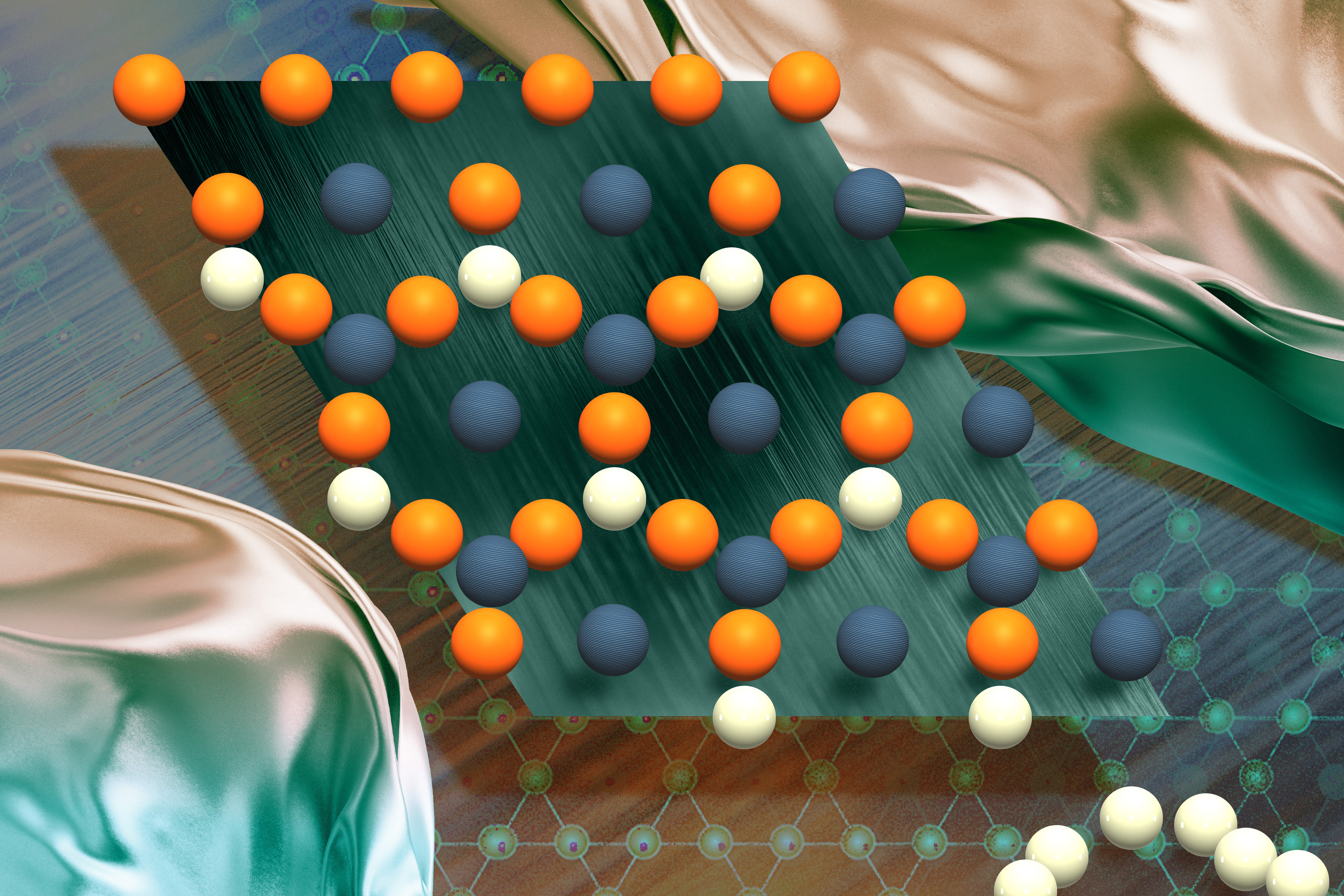

“First, there is hydraulic reactivity. The reason that concrete is strong is that cement — the ‘glue’ that holds it together — hardens when exposed to water. So, if we replace this glue, we need to make sure the substitute reacts similarly,” explains Mahjoubi. “Second, there is pozzolanicity. This is when a material reacts with calcium hydroxide, a byproduct created when cement meets water, to make the concrete harder and stronger over time. We need to balance the hydraulic and pozzolanic materials in the mix so the concrete performs at its best.”

Global Availability of Alternative Materials

Analyzing scientific literature and over 1 million rock samples, the team used the framework to sort candidate materials into 19 types, ranging from biomass to mining byproducts to demolished construction materials. Mahjoubi and his team found that suitable materials were available globally — and, more impressively, many could be incorporated into concrete mixes just by grinding them. This means it’s possible to extract emissions and cost savings without much additional processing.

Examples of Alternative Materials

“Some of the most interesting materials that could replace a portion of cement are ceramics,” notes Mahjoubi. “Old tiles, bricks, pottery — all these materials may have high reactivity. That’s something we’ve observed in ancient Roman concrete, where ceramics were added to help waterproof structures. I’ve had many interesting conversations on this with Professor Admir Masic, who leads a lot of the ancient concrete studies here at MIT.”

Enabling a Circular Economy

The potential of everyday materials like ceramics and industrial materials like mine tailings is an example of how materials like concrete can help enable a circular economy. By identifying and repurposing materials that would otherwise end up in landfills, researchers and industry can help to give these materials a second life as part of our buildings and infrastructure.

Future Plans and Implications

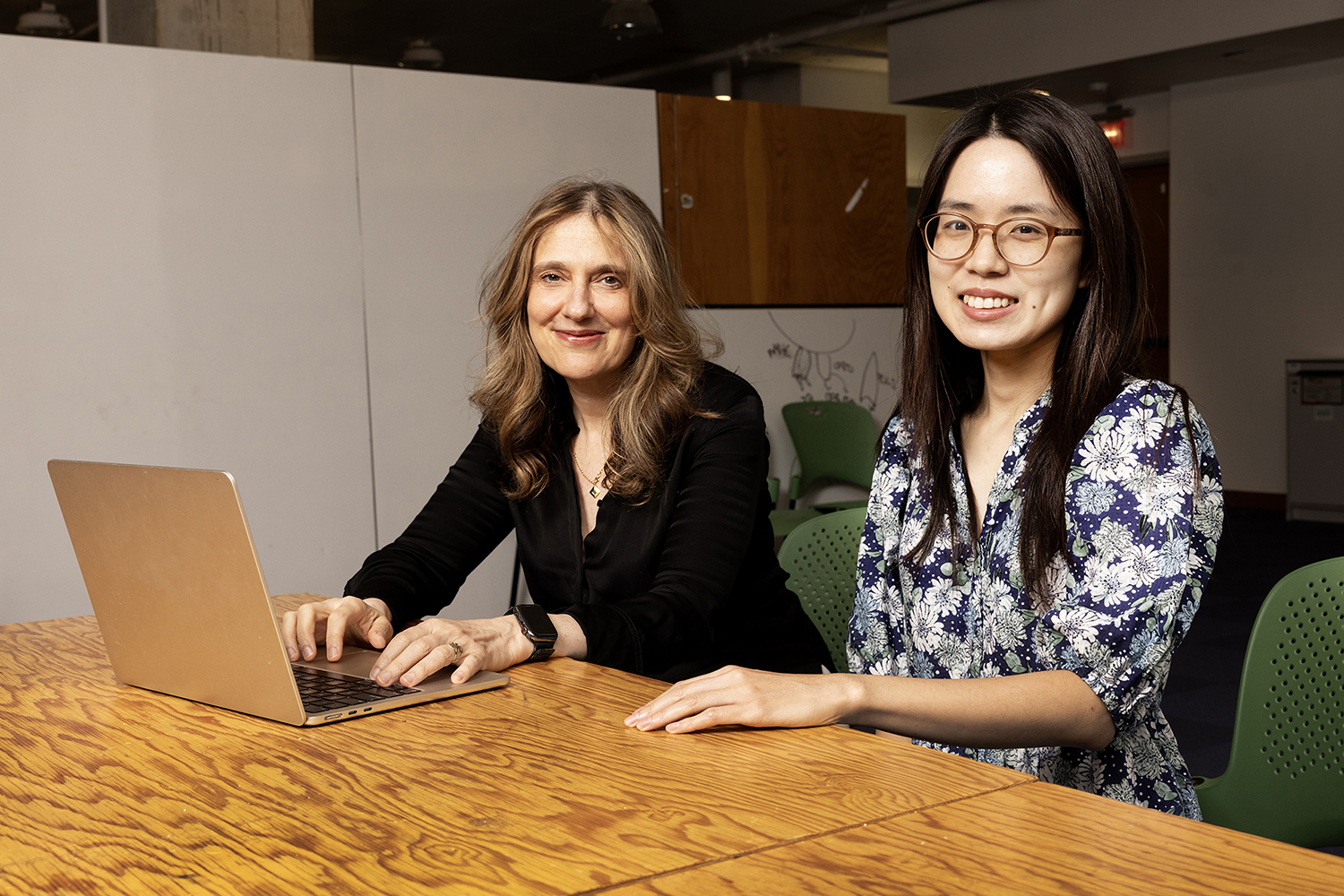

Looking ahead, the research team is planning to upgrade the framework to be capable of assessing even more materials, while experimentally validating some of the best candidates. “AI tools have gotten this research far in a short time, and we are excited to see how the latest developments in large language models enable the next steps,” says Professor Elsa Olivetti, senior author on the work and member of the MIT Department of Materials Science and Engineering.

Conclusion

Concrete is the backbone of the built environment. By applying data science and AI tools to material design, we hope to support industry efforts to build more sustainably, without compromising on strength, safety, or durability. The research team’s findings have significant implications for the construction industry and the environment, and their continued work in this area is crucial for a more sustainable future.

FAQs

Q: What is the main goal of the research team?

A: The main goal of the research team is to reduce the amount of cement in concrete to save on costs and emissions.

Q: How did the team use AI in their research?

A: The team used large language models to build a machine-learning framework that evaluates and sorts candidate materials based on their physical and chemical properties.

Q: What types of materials can replace cement in concrete?

A: The team found that suitable materials include biomass, mining byproducts, demolished construction materials, and ceramics.

Q: What is the potential impact of this research on the environment?

A: The research has the potential to reduce emissions and enable a circular economy by identifying and repurposing materials!