Introduction to Printable Aluminum

MIT engineers have developed a printable aluminum alloy that can withstand high temperatures and is five times stronger than traditionally manufactured aluminum. This new printable metal is made from a mix of aluminum and other elements that the team identified using a combination of simulations and machine learning.

The Development Process

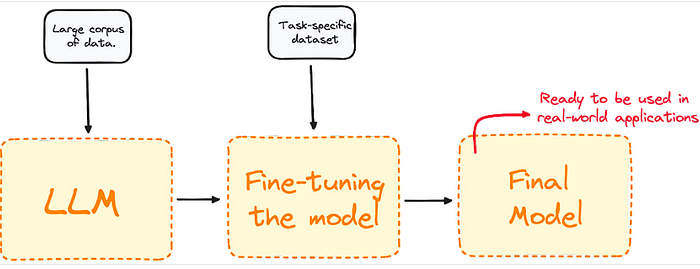

The team used a combination of simulations and machine learning to identify the ideal mix of elements for a high-strength, printable aluminum alloy. While traditional methods would require simulating over 1 million possible combinations of materials, the team’s new machine learning-based approach needed only to evaluate 40 possible compositions before identifying an ideal mix.

Properties of the New Aluminum Alloy

When they printed the alloy and tested the resulting material, the team confirmed that, as predicted, the aluminum alloy was as strong as the strongest aluminum alloys that are manufactured today using traditional casting methods. The new printable aluminum could be made into stronger, more lightweight and temperature-resistant products, such as fan blades in jet engines.

Potential Applications

The researchers envision that the new printable aluminum could be used in advanced vacuum pumps, high-end automobiles, and cooling devices for data centers. According to Mohadeseh Taheri-Mousavi, who led the work as a postdoc at MIT, "If we can use lighter, high-strength material, this would save a considerable amount of energy for the transportation industry."

The Role of Machine Learning

The team used machine-learning techniques designed to efficiently comb through data such as the properties of elements, to identify key connections and correlations that should lead to a more desirable outcome or product. This approach quickly homed in on a recipe for an aluminum alloy with higher volume fraction of small precipitates, and therefore higher strength, than what the previous studies identified.

3D Printing Process

To physically produce this new strong, small-precipitate alloy, the team realized 3D printing would be the way to go instead of traditional metal casting. They considered laser bed powder fusion (LBPF) — a technique by which a powder is deposited, layer by layer, on a surface in a desired pattern and then quickly melted by a laser that traces over the pattern.

Testing and Results

The researchers ordered a formulation of printable powder, based on their new aluminum alloy recipe, and sent it to collaborators in Germany, who printed small samples of the alloy using their in-house LPBF system. The samples were then sent to MIT where the team ran multiple tests to measure the alloy’s strength and image the samples’ microstructure. The results confirmed the predictions made by their initial machine learning search: The printed alloy was five times stronger than a casted counterpart and 50 percent stronger than alloys designed using conventional simulations without machine learning.

Conclusion

The development of a printable aluminum alloy is a significant breakthrough in materials science. The use of machine learning and 3D printing has enabled the creation of a stronger, more lightweight and temperature-resistant material that could have a wide range of applications. As the researchers continue to optimize the properties of the alloy, it is likely that we will see the use of printable aluminum in many industries, from aerospace to automotive.

FAQs

Q: What is the new printable aluminum alloy made of?

A: The new printable aluminum alloy is made from a mix of aluminum and other elements that were identified using a combination of simulations and machine learning.

Q: How strong is the new printable aluminum alloy?

A: The printed alloy is five times stronger than a casted counterpart and 50 percent stronger than alloys designed using conventional simulations without machine learning.

Q: What are the potential applications of the new printable aluminum alloy?

A: The new printable aluminum could be used in advanced vacuum pumps, high-end automobiles, and cooling devices for data centers, as well as in the aerospace industry for fan blades in jet engines.

Q: How was the new printable aluminum alloy developed?

A: The team used a combination of simulations and machine learning to identify the ideal mix of elements for a high-strength, printable aluminum alloy, and then used 3D printing to produce the alloy.

Q: What is the benefit of using machine learning in the development of the new printable aluminum alloy?

A: The use of machine learning enabled the team to quickly identify the ideal mix of elements for a high-strength, printable aluminum alloy, and to optimize the properties of the alloy.