Introduction to AI-Driven Robotic Assembly

Computer-aided design (CAD) systems are powerful tools used to design many of the physical objects we use each day. However, CAD software requires extensive expertise to master, and many tools incorporate such a high level of detail that they don’t lend themselves to brainstorming or rapid prototyping. To make design faster and more accessible for non-experts, researchers from MIT and elsewhere developed an AI-driven robotic assembly system that allows people to build physical objects by simply describing them in words.

How the System Works

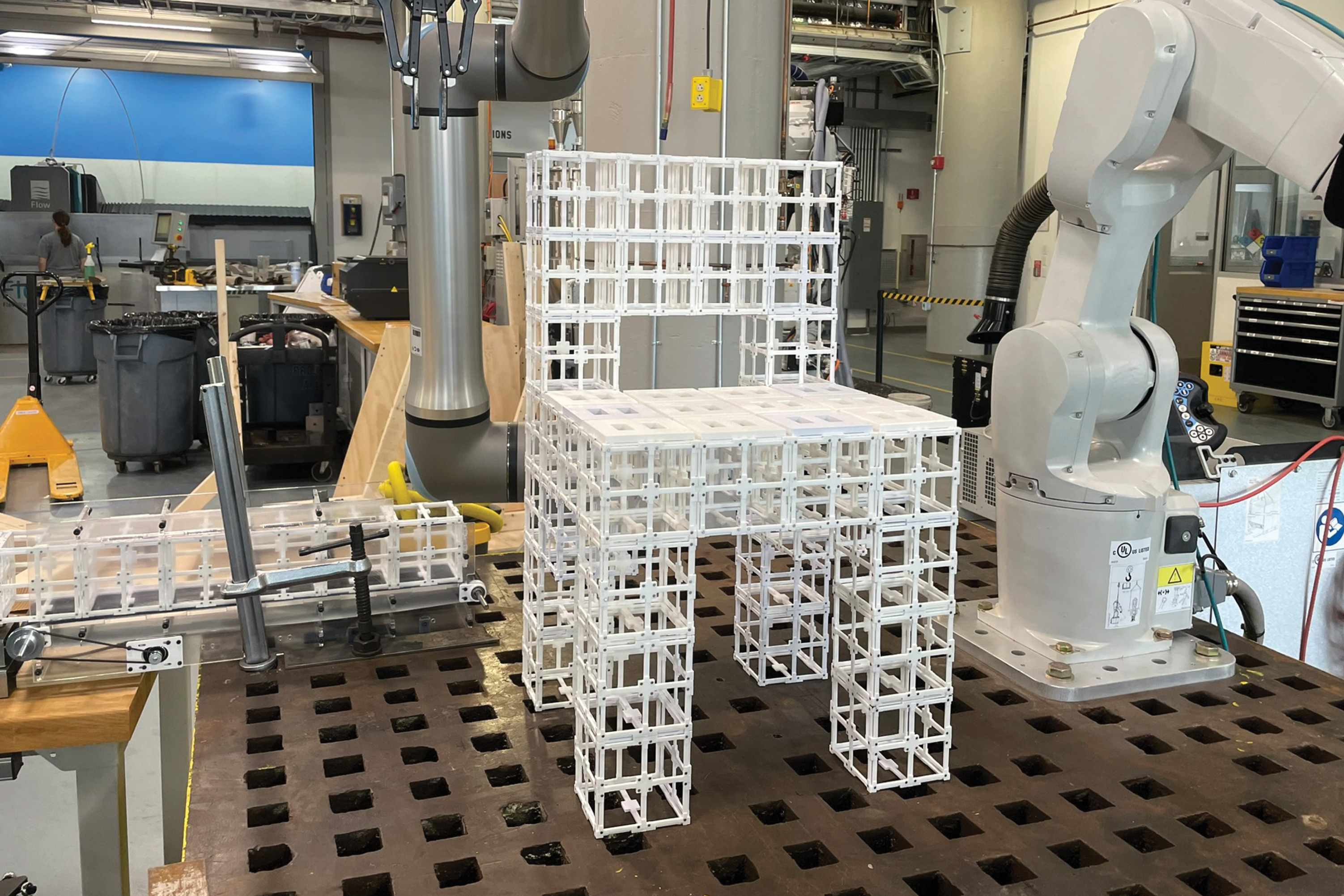

The system uses a generative AI model to build a 3D representation of an object’s geometry based on the user’s prompt. Then, a second generative AI model reasons about the desired object and figures out where different components should go, according to the object’s function and geometry. The system can automatically build the object from a set of prefabricated parts using robotic assembly. It can also iterate on the design based on feedback from the user.

Applications of the System

The researchers used this end-to-end system to fabricate furniture, including chairs and shelves, from two types of premade components. The components can be disassembled and reassembled at will, reducing the amount of waste generated through the fabrication process. This work is an initial demonstration, and the framework could be especially useful for rapid prototyping complex objects like aerospace components and architectural objects. In the longer term, it could be used in homes to fabricate furniture or other objects locally, without the need to have bulky products shipped from a central facility.

Generating a Multicomponent Design

While generative AI models are good at generating 3D representations from text prompts, most do not produce uniform representations of an object’s geometry that have the component-level details needed for robotic assembly. The researchers tackled these challenges using a vision-language model (VLM), a powerful generative AI model that has been pre-trained to understand images and text. They task the VLM with figuring out how two types of prefabricated parts, structural components and panel components, should fit together to form an object.

Human-AI Co-Design

The user remains in the loop throughout this process and can refine the design by giving the model a new prompt. The design space is very big, so the system narrows it down through user feedback. The human-in-the-loop process allows the users to steer the AI-generated designs and have a sense of ownership in the final result. Once the 3D mesh is finalized, a robotic assembly system builds the object using prefabricated parts. These reusable parts can be disassembled and reassembled into different configurations.

Evaluation and Results

The researchers compared the results of their method with an algorithm that places panels on all horizontal surfaces that are facing up, and an algorithm that places panels randomly. In a user study, more than 90 percent of individuals preferred the designs made by their system. They also asked the VLM to explain why it chose to put panels in those areas. The vision language model is able to understand some degree of the functional aspects of a chair, like leaning and sitting, to understand why it is placing panels on the seat and backrest.

Conclusion

The AI-driven robotic assembly system has the potential to drastically lower the barrier of access to design tools. It has shown that it can use generative AI and robotics to turn ideas into physical objects in a fast, accessible, and sustainable manner. The researchers want to enhance their system to handle more complex and nuanced user prompts, such as a table made out of glass and metal. In addition, they want to incorporate additional prefabricated components, such as gears, hinges, or other moving parts, so objects could have more functionality.

FAQs

Q: What is the AI-driven robotic assembly system?

A: The AI-driven robotic assembly system is a tool that allows people to build physical objects by simply describing them in words.

Q: How does the system work?

A: The system uses a generative AI model to build a 3D representation of an object’s geometry based on the user’s prompt, and then a second generative AI model reasons about the desired object and figures out where different components should go.

Q: What are the potential applications of the system?

A: The system could be especially useful for rapid prototyping complex objects like aerospace components and architectural objects, and in the longer term, it could be used in homes to fabricate furniture or other objects locally.

Q: How does the system handle user feedback?

A: The system allows the user to refine the design by giving the model a new prompt, and the design space is narrowed down through user feedback.

Q: What were the results of the user study?

A: In a user study, more than 90 percent of individuals preferred the designs made by the AI-driven robotic assembly system.